Building the Paper Tcîmânens

Making the paper sheet

| It is important to understand that paper has a grain to it. A strip of paper off the end of the roll behaves differently than one cut from along the roll. As the width of the paper is only 35" so one needs to cut strips along the roll to get the required width (47" in this case). A strip cut off the end of the roll tends to curl up along it's length. While one cut from along the roll tends to curl up across the strip. |

|

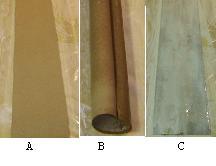

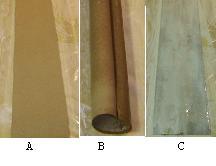

BUILDING THE PAPER SHEET: Given a strip cut along the roll, photo A above, this behavior requires one to wet the off side of the paper strip very well and let the paper curl up before applying the glue, photo B above. Applying the glue results in a nearly flat piece of paper, photo C above. The working width of the paper strips are 4" but narrower stips are need in some cases for gap management. Eleven layers of paper are needed to get the required thickness. This strip may now be added to the base sheet of paper in the press. By starting off various layers at different offsets the paper is applied over the underlaying seams. Each strip is butted next to the previous strip not overlapped. It is easier to work on short sheets of built up paper then working on one large sheet. As the width of the paper is 35" that is a practical length. Four pieces are joined to make up the length required. In order to join the sections into a full sheet the press was placed onto the floor and extensions added to support the sheet. A platform was added to access the press over the sheet; seen beyond the press in the photo. I take the weight, which relates to thickness, for the paper used here as 50 pounds (per ?). |

|

For the finished sheet: Length: 132.5" Weight: 16.5 pounds. Paper : 13 pounds and 6 ozs.(includes a few ounces for experimenting). Glue: About 6.5 quarts. Number Layers: 11 Number Strips: About 400 Number Strips placed per day: 10 - 12 strips. Time to build: 6 - 7 weeks. The inside surface of the sheet was layed-out into a 4" by 4" grid; this grid is used to monitor the shape of the canoe during construction using a laser as described later. |

PANELS:

This style of canoe uses strips of bark along the sides

of the canoe that extend behind the outwale and over

the inwale. This adds strength to the main bark sheet

to prevent tearing do to the pressure exerted by the

ribs.

Six paper panels were constructed (3 per side) each 3 1/4"

by 47" and 6 layers thick using the press. The six panels

weigh 22 ozs (1 pound and 6 ozs).

|

|

REINFORCEMENTS: I decided to make short narrow lengths of paper reinforcements to strength the gores. Three strips of three ply paper that yielded 12 smaller strips of 1 1/4" by 11" were constructed. These will be lashed and glued inside and behind the gores during construction. Gores are vertical slits cut into the paper (or bark) that allow the rectangular paper to map into the complex shape of the canoe. |

Previous page................